Methods to examine the authenticity of documents

I. Examination methods:

- Physical-technical examination with special microscopes and measuring devices combined with different lighting techniques.

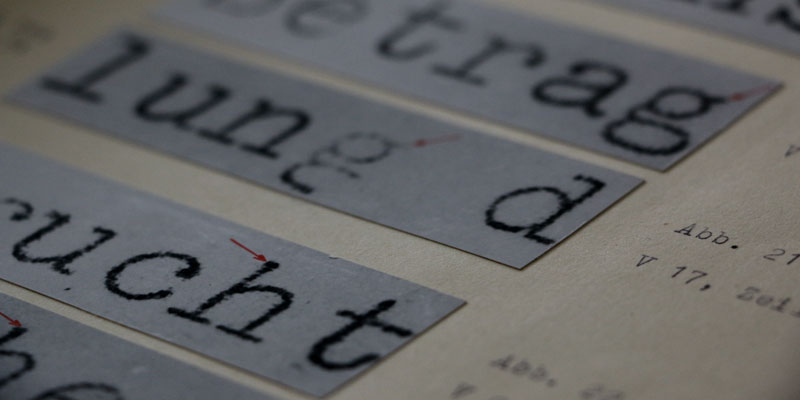

- Classification of the typescript (typewriter, laser or inkjet printer) with an archive of type templates (currently ca. 300,000)

II. Examination options and objectives:

- Identification of the typescript system

To answer the question, what device has been used to produce the typescript. - Determination of the typoscript’s age

To answer the question, whether the age of the typoscript is in accord with the date of the document. Additionally the question “What was the first document?” leads to an interest in the chronological order of documents which can be subject to examination. - Identification of the typescript

To answer the question, if a certain device (typewriter or printer) has been used to produce the document. - Manipulation of typescripts

To answer the question, whether a document has been altered by changing, deleting or adding typescripts. - Reconstruction of typescripts

To redisplay and decipher latent or overwritten texts. - Analysis of ink ribbons

To reconstruct text which has been produced by using a typewriter. - Examination of authorship

To answer the question, if a certain person has used the device by analysing writing characteristics that are specific to this individual.

Examples:

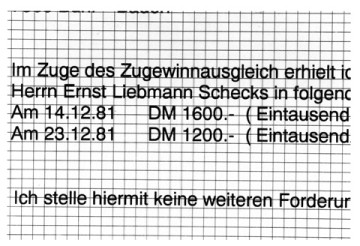

The last line of text was added subsequently in a second printing process with a laser printer. This could be explained by examining the vertical and horizontal parallelism with a special measuring device.

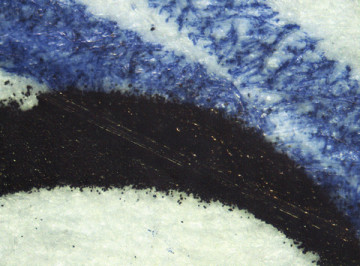

This image shows that the blue pen paste lies above the toner. This could be examined with a special microscope (up to 1500x magnification) that makes it possible to determine the order of the layers of writing devices (e.g. pen paste of a signature and toner of a laser printer).

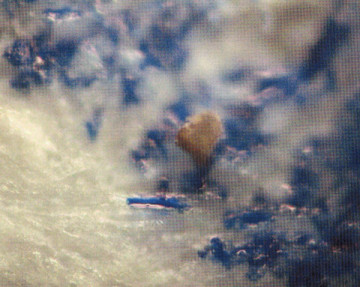

In this example there are so called satellite droplets of an inkjet printer layered above the blue pen paste. This explains that the signature was done in blank.

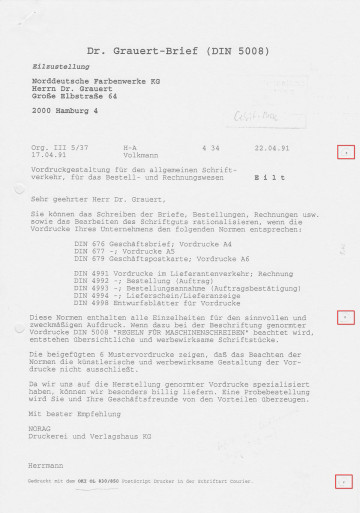

On this standard letter there are impureness details observable which stem from the photoconductor drum of the laser printer. The impureness details can be detected on the right side of the paper with a regular spacing of 9,42 cm. Therefore the laser printout can be related to a specific laser printer.